Axiomatic announces the release of a new generation of machine control interfaces, the Bucket Positioning System (BPS), for continuous assessment of bucket, blade or attachment position as part of a complete 2D or 3D OEM machine control system for off-highway excavators, backhoes, pile drivers or bulldozers.

BPS MACHINE CONTROL INTERFACE, AX180000

Features:

- Hardware Platform for Customer-Specific Embedded Software, Configuration Interface and Drivers

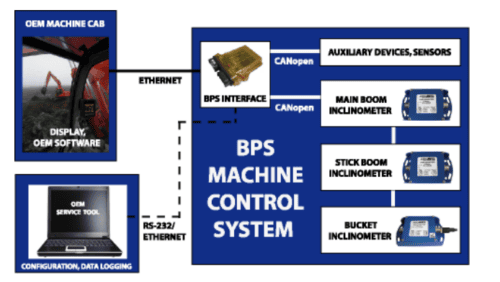

- Can operate with Axiomatic BPS Software and interface with Axiomatic inclinometers as part of a 2D or 3D machine control system featuring continuous assessment of bucket position for hydraulic shovels and excavators

- Interfaces with CANopen® devices for angle sensing (inclinometers)

- Fast data exchange between the BPS interface module and a Machine Control Display via Ethernet

- 2 CAN ports (CANopen® or J1939)

- 1 RS-232 serial COM port for receiving data from a simulation of angle sensors or for configuration and firmware updates as well as for logging raw “real’ sensor information

- 1 Ethernet port for firmware updates and to communicate position and machine specific geometry data to a PC or Display

- Operational from 9 to 36VDC (12V, 24V nominal)

- Integrated Deutsch 2 12-pin connectors (IP69K) and fully sealed enclosure with a rugged IP67 rating

Applications: Machine Control for Mobile (Off-Highway) Equipment – Excavators, Backhoes, Pile Drivers, Bulldozers

The BPS machine control interface via CANopen® calculates and monitors the angular position of multiple inclinometers on an excavator and communicates the data over Ethernet or CAN bus to the operator display in the machine cab. As an OEM application platform, the BPS is a cost-effective solution for integrating machine control systems on a variety of off-highway equipment.

Contact: Amanda Wilkins, Sales and Marketing Manager

TEL: +1 905 602 9270 x224

[email protected]

A PDF version of this press release may be downloaded from: https://www.axiomatic.com/wp-content/uploads/pr-AX180000.pdf.