Axiomatic announces the release of the newest addition to our SAE J1939 Valve Controller Line, the AX022400

DUAL VALVE CONTROLLER,

2 inputs, CAN SAE J1939 –

From Axiomatic,

P/N: AX022400

Axiomatic’s family of rugged valve drivers and I/O modules welcomes the new Dual Valve Controller for extending machine control networks.

The AX022400 DUAL VALVE CONTROLLER interfaces with two fully independent universal command inputs selectable as voltage, current, resistive, frequency, RPM, PWM or digital types. It provides two independent software controlled outputs, up to 3A and selectable as: proportional current, hotshot digital, PWM duty cycle, proportional voltage, or On/Off digital types. The power supply input is 12V, 24V or 48VDC nominal. The input has one provided voltage reference.

The CAN User interface is compliant to SAE CAN J1939 Standard. Users program custom functionality with the Axiomatic Electronic Assistant® software for J1939 models or via an .EDS file with standard service tools for CANopen® Object Dictionary. The dual valve controller can be mounted directly on the valve block or remotely. It is encapsulated in rugged aluminum housing and is suitable for moist, high shock, vibrating and non-hazardous environments. An IP67 rating ensures rugged performance.

Applications:

The controller is designed to meet the rugged demands of mobile equipment, marine and heavy duty industrial machine applications. These applications include, but are not limited to:

- Proportional Fan Drive Control

- PID Closed Loop Valve Control

- Hydraulic Valve Control

- Signal Conversion

Axiomatic provides electronic machine controls, components and systems to the off-highway, military, power generation, material handling, industrial and alternate energy OEM markets. We provide efficient, innovative solutions that focus on adding value for our customers. We emphasize service and partnership with our customers, suppliers, and employees to build long term relationships and mutual trust.

Contact: Amanda Wilkins, Sales and Marketing Manager

TEL: +1 905 602 9270 x224

[email protected]

A PDF version of this press release may be downloaded from: https://www.axiomatic.com/wp-content/uploads/pr-AX022400-May11.pdf.

Axiomatic announces the release of the newest addition to our CANopen Valve Controller Line, the AX022001

UNIVERSAL INPUT, DUAL

VALVE CONTROLLER,

CANopen® – from Axiomatic,

P/N: AX022001

Axiomatic’s family of rugged valve drivers and I/O modules welcomes the new CANopen® Dual Valve Controller for extending machine control networks.

AX022001 DUAL HYDRAULIC VALVE CONTROL interfaces with a universal input signal and CAN bus to drive 2 valves: proportional or hotshot digital current (0-3A); or proportional V or PWM; or on/off. The universal input reads a command signal: voltage; current; resistive; frequency; or digital. A +5V reference sources up to 10mA for a potentiometer or low-power transducer. Built-in protection features are enabled for safety critical systems. Users program custom functionality with the Axiomatic Electronic Assistant® software for J1939 models or via an .EDS file with standard service tools for CANopen® Object Dictionary. An IP67 rating ensures rugged performance.

Applications:

Machine Control – An integral part of a hydraulic control subsystem for construction equipment (excavators).

Axiomatic provides electronic machine controls, components and systems to the off-highway, military, power generation, material handling, industrial and alternate energy OEM markets. We provide efficient, innovative solutions that focus on adding value for our customers. We emphasize service and partnership with our customers, suppliers, and employees to build long term relationships and mutual trust.

Contact: Amanda Wilkins, Sales and Marketing Manager

TEL: +1 905 602 9270 x224

[email protected]

A PDF version of this press release may be downloaded from: https://www.axiomatic.com/wp-content/uploads/pr-AX022001-Feb11.pdf.

Axiomatic announces the release of the newest addition to our Signal Conditioner Line, the AX130200

By providing a signal conversion and isolation between two incompatible signals, the Axiomatic AX130200 can assist the system integrator to connect several different devices in a control system.

This model converts a Pulse Width Modulated (PWM) Signal between 50 Hz to 50 kHz into a 0-20 mA current signal and provides full isolation between input, output and power supply. With DIN rail housing, screw terminal connections and an LED indicator, this converter has user friendly adjustability.

The PWM to Current Converter is part of a growing line of signal conditioners designed and manufactured by Axiomatic. Single or multiple channel signal conditioners convert and manage several digital PWM, voltage or current signals in order to suit a variety of machine control and automation applications. Axiomatic’s high-efficiency converters are easily customized to meet specific application needs.

Features:

- PWM input (50 Hz to 50 kHz, 0-100% Duty Cycle)

- Other current or voltage inputs available on request

- 0-20 mA output (model AX130200)

- 4-20 mA, 0-5VDC, 0-10VDC outputs available

- 12VDC or 24VDC nominal power supply

- Full Isolation between input, output and power supply

- Short circuit protection

- DIN rail mount (35mm)

- <5 mSec. response time

- Diagnostic LEDs indicate operational status

- Operational from -40 to 85 degrees C

- PCB is conformal coated

- IP40 housing protection, terminals rated at IP20

- Span and zero is user adjustable.

Applications: Distributed controls for machine or engine control panels, Industrial automation

Contact: Amanda Wilkins, Sales and Marketing Manager

TEL: +1 905 602 9270 x224

[email protected]

A PDF version of this press release may be downloaded from: https://www.axiomatic.com/wp-content/uploads/pr-AX130200-nov10.pdf.

Axiomatic announces the release of three new CANopen® engine management controls

The Axiomatic 20 or 4 Thermocouple (TC) and 8 RTD Scanners send engine low or high temperature warnings, detect high temperature shutdowns and sense TC or RTD open circuit conditions. The module communicates over CANopen® to the control system of an industrial genset. Axiomatic announces the release of three new CANopen® engine management controls, part numbers AXTC20CO, AXTC4CO and AXRTD8CO respectively. These controllers are part of a growing line of low cost and rugged distributed I/O controls for CAN networks and packaged for harsh operating environments.

20 Thermocouple Scanner, CANopen®

(8 RTD model is available with the same packaging.)

Features:

Model AXTC20CO: 20 Thermocouple Inputs, CANopen®

- Accepts 20 type J, K, B, E, N, R, S or T thermocouples (8 RTD input model available)

- Temperature is measured in ºC, with a 0.001ºC resolution.

- The scanner will send temperatures with +/- 1ºC accuracy.

- Cold junction compensation is provided as an enable/disable function.

- It flags low temperature warnings, high temperature warnings, or high temperature shutdowns to the engine control system.

- Average temperature of all the active channels, or all channels from a block of 10, can be broadcasted to the CAN network.

- It detects open circuits on the sensor wires.

- 12V, 24V or 48VDC input power (nominal).

- All channels are fully isolated from each other, the CAN lines, and from the power supply.

- 1 CANopen® port (SAE J1939 available)

- 1 RS-232 port

- Rugged IP65 packaging and connectors

- Configurable with commercially available CANopen® tools (not supplied)

4 Thermocouple Scanner, CANopen®

Features:

Model AXTC4CO: 4 Thermocouple Inputs, CANopen®

- Accepts 4 Type J, K or T thermocouples

- Temperature is measured in ºC, with a 0.001ºC resolution.

- The scanner will send temperatures with +/- 1ºC accuracy.

- Cold junction compensation is provided as an enable/disable function.

- It flags low temperature warnings, high temperature warnings, or high temperature shutdowns to the engine control system.

- The average temperature of all the active channels, or all channels from a block of 2, can be broadcasted to the CAN network.

- It detects open circuits on the sensor wires.

- 12V, 24V, 48V or 60VDC input power (nominal)

- All channels are fully isolated from each other, the CAN lines, and from the power supply.

- 1 CANopen® port (SAE J1939 available)

- 1 RS-232 port

- Rugged IP67 packaging and connectors

- Configurable with commercially available CANopen® tools (not supplied)

Applications (Both P/Ns):

• Distributed controls for industrial power gen sets and backup power engine control systems

Contact: Amanda Wilkins, Sales and Marketing Manager

TEL: +1 905 602 9270 x224

[email protected]

A PDF version of this press release may be downloaded from: https://www.axiomatic.com/wp-content/uploads/pr-AXTC20CO-sept10.pdf.

Drive hydraulic valves cost effectively from your machine CAN control network with the new Axiomatic controller

Drive hydraulic valves cost effectively from your machine CAN control network with the new Axiomatic controller, the CAN bus to 1 Valve Driver. Read analog sensors with the 1 Universal Signal Input with CAN I/O controller.

Axiomatic announces the release of a new SAE J1939 or CANopen® valve driver and I/O control, part numbers AX022200 and AX030530 respectively. These controllers are part of a growing line of low cost and compact rugged distributed I/O controls packaged for harsh operating environments.

CAN bus to 1 Valve Driver

Features:

Model AX022200:

- 1 Valve Driver Output

- 1 proportional output up to 2A

- Or a configurable on/off output up to 3A

- 12V or 24VDC input power (nominal) with rugged surge protection

- 1 CAN (SAE J1939) port – CANopen® on request

- Rugged IP67 packaging and connectors

- Programmable with PC-based Axiomatic Electronic Assistant

SINGLE CHANNEL I/O with CAN bus

Features:

Model AX030530:

- 1 Universal Analog Signal Input (Voltage, Current, Resistive, Digital, Frequency or PWM)

- User selectable input range from: 0-1V; 0-2.5V; 0-5V; 0-10V; 0-20mA; 4-20 mA; 20 Ohms to 250 kOhms; 10Hz –1 kHz; or 100 Hz – 10 kHz.

- 12V/24V/48VDC input power (nominal) with rugged surge protection

- Galvanic isolation between power supply and analog signal output

- 1 SAE J1939 port

- Rugged IP67 packaging and connectors

- Programmable with PC-based Axiomatic Electronic Assistant

Applications (both P/Ns):

- Distributed controls for commercial vehicles, off-highway equipment, industrial equipment, etc.

- Distributed controls for power generation, co-generation, stationary power.

Note:

Electronic Assistant® is a registered trademark of Axiomatic Technologies Corporation.

Contact: Amanda Wilkins, Sales and Marketing Manager

TEL: +1 905 602 9270 x224

[email protected]

A PDF version of this press release may be downloaded from: https://www.axiomatic.com/wp-content/uploads/pr-AX022200-aug10.pdf.

Axiomatic announces its newest hydraulic valve driver

Axiomatic announces its newest hydraulic valve driver, the AX021900 8:5 Valve Control with CAN, designed to improve productivity and reduce emissions in mobile equipment. It is suited for OEM control applications such as fan drive systems and transmission controls.

Axiomatic’s cost effective hydraulic valve controllers and fan controllers are designed for a variety of applications such as road construction and agricultural equipment. They are built with rugged environmental and mechanical features to suit such harsh environments. The sophisticated processing capabilities of our standard platforms along with Axiomatic’s application engineering services for custom applications offer a wide choice of solutions to the machine designer needing to control primary functions or add auxiliary functions.

This new 8:5 Valve Controller is designed to control 5 proportional or on/off solenoid valves from a variety of input sources. It accepts voltage, current, resistance, frequency, digital, and PWM from six universal inputs. This Valve Controller offers the end user a high value/cost ratio. With superior processing technology which includes user configurable PID capability, the AX021900 controller is an economical solution to meet the complex control requirements of many standard functions on an off highway machine today.

Features:

- 6 universal analog signal inputs (current, voltage, resistive, frequency, digital or PWM)

- 1 digital input for enable/disable functionality

- 1 magnetic pickup sensor input (RPM)

- 4 proportional or on/off valve drivers up to 2.5 A

- Open or closed loop (PID) drive is user configurable.

- 1 digital output up to 2.5A

- Fully protected outputs.

- 1 CAN (SAE J1939) port (CANopen® on request)

- 12V, 24V or 48V nominal

- Rugged IP67 packaging and connectors for harsh environments

- Flexible user programming for application-specific control logic via the CAN based Axiomatic Electronic Assistant

Typical applications can include:

- Industrial, off-highway (mobile) and marine applications for the control of hydraulic proportional poppet or spool valves

- Closed loop control of hydraulic valves

- Interface with a diesel engine’s electronic control module PWM signal to drive accessories

- Transmission controls

- Fan drive controls

- Vehicle traction control (on request)

Axiomatic’s family of SAE J1939 and CANopen® controls help the machine designer meet emission requirements and improve productivity. Contact Axiomatic for an application-based control solution!

In addition to our wide range of I/O and hydraulic valve drivers with new functionality, Axiomatic can now offer control options for actuating DC motors, BLDC motors, powering lighting and auxiliary devices as well as battery charging.

Contact: Amanda Wilkins, Sales and Marketing Manager

TEL: +1 905 602 9270 x224

[email protected]

A PDF version of this press release may be downloaded from: https://www.axiomatic.com/wp-content/uploads/pr-AX021900-july10.pdf.

Axiomatic announces the release of a new generation of machine control interfaces

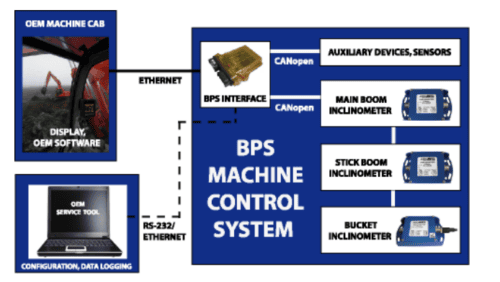

Axiomatic announces the release of a new generation of machine control interfaces, the Bucket Positioning System (BPS), for continuous assessment of bucket, blade or attachment position as part of a complete 2D or 3D OEM machine control system for off-highway excavators, backhoes, pile drivers or bulldozers.

BPS MACHINE CONTROL INTERFACE, AX180000

Features:

- Hardware Platform for Customer-Specific Embedded Software, Configuration Interface and Drivers

- Can operate with Axiomatic BPS Software and interface with Axiomatic inclinometers as part of a 2D or 3D machine control system featuring continuous assessment of bucket position for hydraulic shovels and excavators

- Interfaces with CANopen® devices for angle sensing (inclinometers)

- Fast data exchange between the BPS interface module and a Machine Control Display via Ethernet

- 2 CAN ports (CANopen® or J1939)

- 1 RS-232 serial COM port for receiving data from a simulation of angle sensors or for configuration and firmware updates as well as for logging raw “real’ sensor information

- 1 Ethernet port for firmware updates and to communicate position and machine specific geometry data to a PC or Display

- Operational from 9 to 36VDC (12V, 24V nominal)

- Integrated Deutsch 2 12-pin connectors (IP69K) and fully sealed enclosure with a rugged IP67 rating

Applications: Machine Control for Mobile (Off-Highway) Equipment – Excavators, Backhoes, Pile Drivers, Bulldozers

The BPS machine control interface via CANopen® calculates and monitors the angular position of multiple inclinometers on an excavator and communicates the data over Ethernet or CAN bus to the operator display in the machine cab. As an OEM application platform, the BPS is a cost-effective solution for integrating machine control systems on a variety of off-highway equipment.

Contact: Amanda Wilkins, Sales and Marketing Manager

TEL: +1 905 602 9270 x224

[email protected]

A PDF version of this press release may be downloaded from: https://www.axiomatic.com/wp-content/uploads/pr-AX180000.pdf.

Add legacy controls cost effectively to your CAN network with the new Axiomatic controllers

Add legacy controls cost effectively to your CAN network with the new Axiomatic controllers, CAN – 4 Analog Signal and CAN – 1 Analog Signal. Read analog sensors with the 1 Universal Signal Input – CAN control.

Axiomatic announces the release of a new SAE J1939 or CANopen® I/O control with 4 analog signal outputs, part number AX030500 and AX030501 respectively. These controllers are part of a growing line of low cost and compact rugged distributed I/O controls packaged for harsh operating environments. Other new models include a CAN to 1 Analog Signal Output I/O Control, p/n AX030520, and a 1 Universal Signal Input to CAN I/O Module, p/n AX030530.

SINGLE CHANNEL I/O (CAN Input, 1 Output)

MULTIPLE CHANNEL (1 Input, 4 Outputs)

Applications:

- Distributed controls for power generation, co-generation, stationary power

- Distributed controls for commercial vehicles, off-highway equipment, industrial equipment, etc.

Features:

Model AX030520: 1 Voltage or Current Output

- User selectable output range from +/-10V or +/-20 mA, including: 0-5V; 0-10V; +/-5V; +/-10V; 0-20mA; 4-20 mA; and +/-20mA.

Model AX030530: 1 Universal Analog Signal Input (Voltage, Current, Resistive, Digital, Frequency or PWM)

- User selectable input range from: 0-1V; 0-2.5V; 0-5V; 0- 10V; 0-20mA; 4-20 mA; 20 Ohms to 250 kOhms; 10Hz –1 kHz; or 100 Hz – 10 kHz.

- 12V/24V/48VDC input power (nominal) with rugged surge protection

- Galvanic isolation between power supply and analog signal output

- 1 SAE J1939 port

- Rugged IP67 packaging and connectors

- Programmable with the PC-based Axiomatic Electronic Assistant

Models AX030500, AX030501:

- 4 independent analog signal outputs (voltage or current)

- User selectable output range from +/-10V or +/-20 mA, including: 0-5V; 0-10V; +/-5V; +/-10V; 0-20mA; 4-20 mA; and +/-20mA.

- 12V/24V/48VDC input power (nominal) with rugged surge protection

- Galvanic isolation between power supply and analog signal outputs

- 1 SAE J1939 or CANopen® port

- Rugged IP67 packaging and connectors

- TE Deutsch EEC housing

- Programmable with the PC-based Axiomatic Electronic Assistant (SAE J1939 model only)

Contact: Amanda Wilkins, Sales and Marketing Manager

TEL: +1 905 602 9270 x224

[email protected]

A PDF version of this press release may be downloaded from: https://www.axiomatic.com/wp-content/uploads/pr-AX030501-april10.pdf.

Axiomatic’s family of SAE J1939 and CANopen® controls help the machine designer meet emission requirements and improve productivity

Axiomatic’s family of SAE J1939 and CANopen® controls help the machine designer meet emission requirements and improve productivity. Contact Axiomatic for an application-based control solution!

In addition to our wide range of I/O and hydraulic valve drivers with new functionality, Axiomatic can now offer control options for actuating DC motors, BLDC motors, powering lighting and auxiliary devices as well as battery charging.

Missing an I/O?

Expand your CAN control system with the CAN-1 Valve Driver.

Want to add legacy controls to the CAN bus?

Use the CAN – 1 Analog Signal AX030520.

Wish to integrate valves with on-onboard electronics but no CAN?

Interface to the CAN network and command electrohydraulic valves with the CAN-1 Analog Signal AX030520.

Need to read analog sensors?

Connect the 1 Analog Signal – CAN AX030530.

Need to charge batteries and communicate charge status over CAN bus?

Utilize the SAE J1939 Battery Charger – AX090300.

Axiomatic’s cost effective hydraulic valve controllers and fan controllers are well suited for a variety of applications such as road construction and agricultural equipment. They are built with rugged environmental and mechanical features to suit such harsh environments. The sophisticated processing capabilities of our standard platforms along with Axiomatic’s application engineering services for custom applications offer a wide choice of solutions to the machine designer needing to add auxiliary functions. Models include CAN bus – valve driver outputs as well as multiple switch and analog inputs to multiple valve driver outputs. All controls are available in SAE J1939 or CANopen® models. Utilize the AX020XXX family of valve controllers and interface with the AX030XXX family of CAN/Analog I/O modules to create your networked solution.

Axiomatic displays can capture data on the CAN network and provide feedback on critical machine operating and diagnostic parameters. Key to our SAE J1939 controllers is the Axiomatic Electronic Assistant programming tool, P/N AX070502, for initial setup and service of Axiomatic controls. Users can map inputs and outputs, enter and save setpoints for simple user friendly customization as well as see graphical data and monitor CAN messages during service.

To power sensitive controls from a battery-based system, Axiomatic also offers a full range of DC-DC converters.

Axiomatic continues to expand our product line and capabilities to solve customer needs.

About Axiomatic Technologies – Axiomatic Technologies provides electronic machine controls, components and systems to the off-highway, military, power generation, material handling, industrial and alternate energy OEM markets. We provide efficient, innovative solutions that focus on adding value for our customers. We emphasize service and partnership with our customers, suppliers, and employees to build long term relationships and mutual trust. More details are available at www.axiomatic.com.

Note: CANopen® is a registered community trade mark of CAN in Automation e.V.

Contact: Amanda Wilkins, Sales and Marketing Manager

TEL: +1 905 602 9270 x224

[email protected]

A PDF version of this press release may be downloaded from: https://www.axiomatic.com/wp-content/uploads/pr-Axiomaticlineup.pdf.

Axiomatic’s family of rugged inclinometers and tilt sensors has a series of new low cost sensors

UNIVERSAL INCLINOMETER, CANopen®

SERIES – from Axiomatic, P/N: AX06025X

Axiomatic’s family of rugged inclinometers and tilt sensors has a series of new low cost sensors that can measure ±90º degrees or 360 degrees angular rotation. The AX06025X series features CANopen networking, a RS-232 port or 3 Voltage Outputs for communicating the angular measurement. The inclinometer series also supports the SAE J1939 CAN interface under the p/n’s AX0602XX. The J1939 inclinometer is fully configurable using the Axiomatic Electronic Assistant programming tool for PCs. All units are packaged for an IP67 rating with M12x2 5-pin connectors or a M12 x1 5-pin. A mating plug with CAN termination resistor is available.

The inclinometer is designed to measure inclination angle in two orthogonal sensing directions X and Y in the range of up to ±90º. If vertically installed, it can measure an inclination angle in one sensing direction in the ±180º (0-360º) range.

The angles are measured by a two-axis MEMS sensor, which senses acceleration caused by the gravity force. The output signals from the MEMS sensor are normalized and processed by a microcontroller to receive inclination angles. The resolved angles can be then sent to the CAN bus, RS232 port or output as 3 0-5V signals.

Due to a powerful microcontroller, the inclinometer can perform pre-processing of the angular information according to the users’ needs. Its internal architecture is user-programmable and allows users to define their own custom functionality using a set of predefined internal functional blocks. For J1939 models, application programming is performed through the CAN interface by the PC-based Axiomatic Electronic Assistant software. For CANopen® models, application programming is achieved via standard and commercially-available tools for CANopen®.

In a tilt sensor application, an out-of-range state can be transmitted as one of its outputs.

Applications:

Inclinometer – An integral part of a position control system or subsystem for construction equipment (excavators)

and after-market excavator attachments.

Tilt Sensor – Provides out of level indication for lift equipment and other machines.

Axiomatic provides electronic machine controls, components and systems to the off-highway, military, power generation, material handling, industrial and alternate energy OEM markets. We provide efficient, innovative solutions that focus on adding value for our customers. We emphasize service and partnership with our customers, suppliers, and employees to build long term relationships and mutual trust.

Contact: Amanda Wilkins, Sales and Marketing Manager

TEL: +1 905 602 9270 x224

[email protected]

A PDF version of this press release may be downloaded from: https://www.axiomatic.com/wp-content/uploads/pr-inclinometer-april-19-10.pdf.